ABOUT ME

I’m Piers and I’m a welder from Birmingham. I understand metal and metal does what I want it to. My strong inventive streak often has to be reined in. If you can imagine it, and the laws of physics allow for it, I’ll work with you to realise your vision.

Read more about me by clicking the arrow below.

Piers Gilmore

I’ve been tinkering and fixing things ever since I can remember. Lego and Meccano weren’t just toys, they were an obsession and my dad couldn’t trust me anywhere near his tool box. So I set up a secret lab in the cellar.

The only lessons at school that held my attention for any amount of time were the design and technology classes and if anything I didn’t find them challenging enough. I was even awarded a prize for technology after I took it upon myself to create a functioning crossbow. However, not many educational institutions appreciated my one trick pony attitude towards their curriculum so a decision was made and at 17 I left school.

I ended up operating a mill and a lathe in a pattern maker’s workshop in the Black Country. There I learned that the most important rule was to make a bad cup of tea. I then attended Warwickshire college for a year to train in traditional blacksmithing, because why not, eh?.

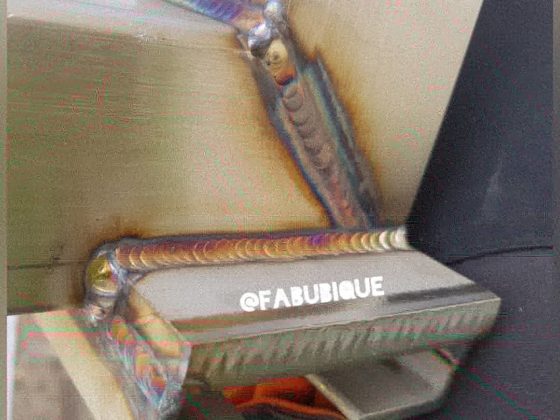

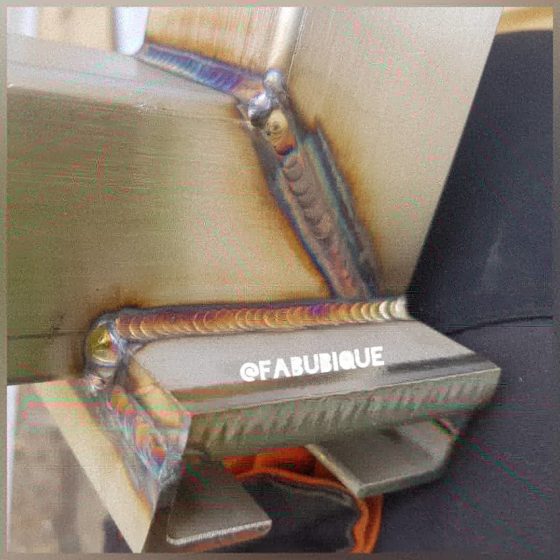

After leaving the Army I needed a job and went back to welding. I worked my way up rapidly from making cheap shop furniture to eventually welding titanium pipework for the aerospace industry. I tired of having a boss and started subcontracting as a pipe welder. A personal highlight of this was fitting the brewery at the new Tottenham Hotspurs stadium.

I then must have had a knock on the head because I found myself in the army for 7 years. 5 of those years were spent in the Royal Engineers during which I was recommended for Clerk of Works and placed top of my fabrication and welding course. Then, for some reason, I went into student nursing for my remaining 2 years.

Now I want to make stuff for you!

I understand metal and metal does what I want it to. My strong inventive streak often has to be reined in. If you can imagine it, and the laws of physics allow for it, I’ll work with you to realise your vision. Feel free to take a glance at my portfolio and message me with any questions.

MY SERVICES

Having worked in industries ranging from heavy fabrications through to titanium pipework for the aerospace industry, I have a wide range of technical experience. However, behind this experience there’s an artistic and inventive streak that inspires some truly unique work. My knowledge of various welding processes, brazing, soldering, fabrication and forge work allow me to provide the product you need.

Commercial

When I moved into the world of subcontracting, I began by working as a fabricator/mechanical fitter, but it wasn’t long before I was given the opportunity to qualify for my 6G TIG codes. Since then I have also gained my IPAF (a&b) and my blue CSCS card. Some of the more notable projects that I have worked on have been an experimental hydrogen fuel refinery (during which I was filmed working by Tomorrow’s World) and piping in the brewery for the new Tottenham Hotspur Stadium.

Private Commissions

Having gone to college at 17 to train as a blacksmith, my early experience of metalwork came from a very artistic perspective. This never really left me and during quiet moments I could often be found making little sculptures for the people that are special to me, I’m proud to say that this has led to a couple of small sculptures being privately commissioned. My bespoke decorative iron work is always unique to the customer and rarely fails to impress.

Interested?

PIERS@BOOTSNBLISTERS.COM | 0121 454 4624

Contact me!

Have any questions or queries? Want to leave me a message? Leave your information in the form below and I’ll get back to you!

Boots & Blisters Welding Collective Limited, 2020. Website made with ♥ by LearnPlay Foundation.

mobile/tablet view

ABOUT ME

I’m Piers and I’m a welder from Birmingham. I understand metal and metal does what I want it to. My strong inventive streak often has to be reined in. If you can imagine it, and the laws of physics allow for it, I’ll work with you to realise your vision.

Read more about me by clicking the arrow below.

I’ve been tinkering and fixing things ever since I can remember. Lego and Meccano weren’t just toys, they were an obsession and my dad couldn’t trust me anywhere near his tool box. So I set up a secret lab in the cellar.

The only lessons at school that held my attention for any amount of time were the design and technology classes and if anything I didn’t find them challenging enough. I was even awarded a prize for technology after I took it upon myself to create a functioning crossbow. However, not many educational institutions appreciated my one trick pony attitude towards their curriculum so a decision was made and at 17 I left school.

I ended up operating a mill and a lathe in a pattern maker’s workshop in the Black Country. There I learned that the most important rule was to make a bad cup of tea. I then attended Warwickshire college for a year to train in traditional blacksmithing, because why not, eh?.

I then must have had a knock on the head because I found myself in the army for 7 years. 5 of those years were spent in the Royal Engineers during which I was recommended for Clerk of Works and placed top of my fabrication and welding course. Then, for some reason, I went into student nursing for my remaining 2 years.

After leaving the Army I needed a job and went back to welding. I worked my way up rapidly from making cheap shop furniture to eventually welding titanium pipework for the aerospace industry. I tired of having a boss and started subcontracting as a pipe welder. A personal highlight of this was fitting the brewery at the new Tottenham Hotspurs stadium.

Now I want to make stuff for you!

I understand metal and metal does what I want it to. My strong inventive streak often has to be reined in. If you can imagine it, and the laws of physics allow for it, I’ll work with you to realise your vision. Feel free to take a glance at my portfolio and message me with any questions.

MY SERVICES

Having worked in industries ranging from heavy fabrications through to titanium pipework for the aerospace industry, I have a wide range of technical experience. However, behind this experience there’s an artistic and inventive streak that inspires some truly unique work. My knowledge of various welding processes, brazing, soldering, fabrication and forge work allow me to provide the product you need.

Commercial

When I moved into the world of subcontracting, I began by working as a fabricator/mechanical fitter, but it wasn’t long before I was given the opportunity to qualify for my 6G TIG codes. Since then I have also gained my IPAF (a&b) and my blue CSCS card. Some of the more notable projects that I have worked on have been an experimental hydrogen fuel refinery (during which I was filmed working by Tomorrow’s World) and piping in the brewery for the new Tottenham Hotspur Stadium.

Private Commissions

Having gone to college at 17 to train as a blacksmith, my early experience of metalwork came from a very artistic perspective. This never really left me and during quiet moments I could often be found making little sculptures for the people that are special to me, I’m proud to say that this has led to a couple of small sculptures being privately commissioned. My bespoke decorative iron work is always unique to the customer and rarely fails to impress.

Let’s plan our next project together!

PIERS@BOOTSNBLISTERS.COM

0121 454 4624

Contact me!

Have any questions or queries? Want to leave me a message? Leave your information in the form below and I’ll get back to you!